Max. bag width 800mm

Max. printing width 700mm

Printing speed 30-80m/min

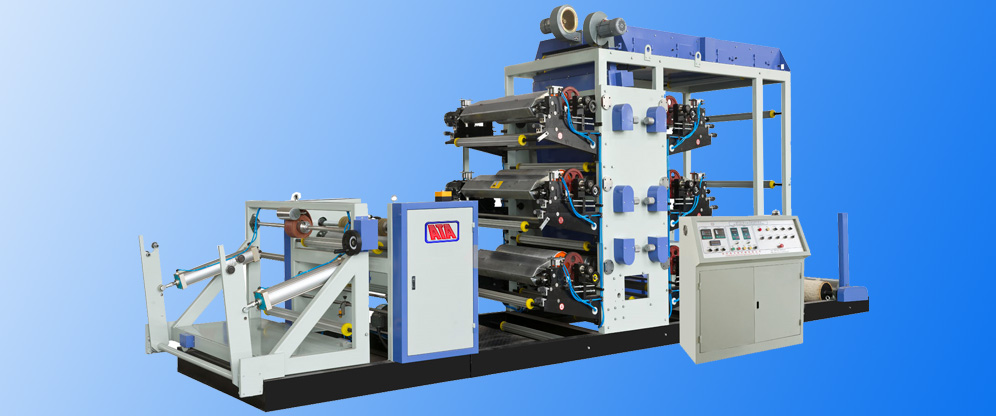

The machine adds a leveling mechanism with reference to foreign technology. When the host is stopped, the ink transfer mechanism continues to work, and the waiter can be restarted to reduce the generation of printing waste

Note: This series of models are available in 4, 6, 8, 10, and 12 colors. This description uses 6 colors as an example.

|

pos |

Description |

|

1

|

Unwinder The unwinder is equipped with an automatic correcting device and a unique pneumatic installation cloth roll method, which is easy to use.

correcting device: Photoelectric correction taiwan Roll up cylinder: QGB100×500 2pcs Frequency converter ouri

|

|

1

|

Printing system Japan's Mitsubishi PLC controls the whole machine operation. When the machine is stopped, the uniform ink motor works automatically to maintain the uniformity of the ink. Re-start to reduce waste, Two working position unwinding (one standby, one unwinding). Printing system overlay accuracy may be horizontal 40mm, vertical 360o non-stop adjustment, variable frequency control speed.

Main motor: 63kw Frequency converter: 7kw Printing steel roll: Φ132X850mm Automatic ink circulation PLC: Mitsubishi Japan

|

|

1

|

Drying system The drying system is independent of the printing system and can automatically control the oven temperature according to the actual control of the drying effect.

Constant temperature oven 2pcs Automatic Control System 2pcs

|

|

1

|

unwinder The winder adopts friction winding, The tension is stable, ensuring the flatness of the cloth roll.

|

|

1

|

Electrical Control Panel

|

| Color | Two Sides 6 Colors(6+0,5+1,4+2,3+3 ) |

| Max. bag width | 800mm |

| Max. printing width | 700mm |

| Max. printing langth | 1200mm |

| Printing speed | 30-80m/min |

| Thickness of Printing Plate | 4mm |

| Unwinding cloth diameter | Φ1200 mm |

| Power connection | 20KW |

| Machine weight | About 5T |

| Dimension (lay-out) | 9000x2000x3000mm |

HOME

HOME