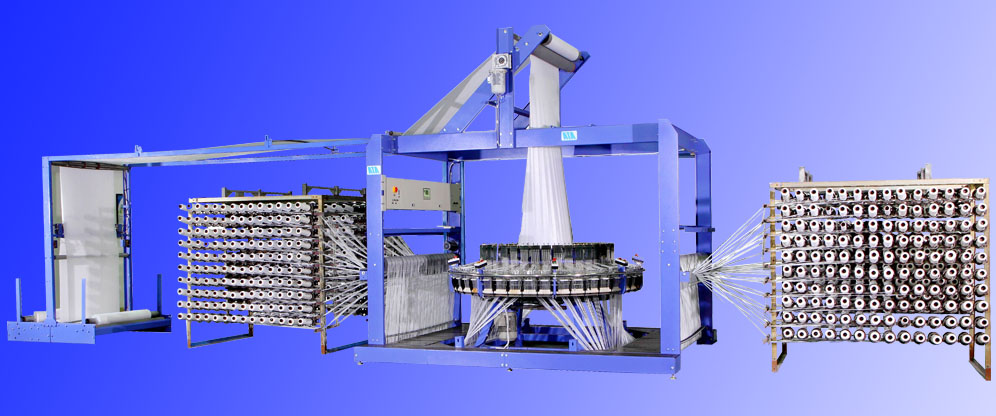

Fold width 800-1250mm

Shuttle number 6pcs

Weft insertion (max.) 840ppm

Qty Description

1 Main machine

42 sets of heddle belt + heddle wire, 24 of heddle wires stations in each group, totaling 1008pcs.

Rolling reed structure is beneficial to the oil-free fabric, enhances the film coating effect, and meets the requirements of food-grade products.

The main motor is Siemens variable frequency drive.

With automatic refueling cup, you can set the refueling time and fueling amount on the control screen.

6 Shuttle

The shuttle is equipped with an automatic weft yarn tension control device.

The shuttle is equipped with front and back Block yarn plate, Max.can loading 110mm diameters weft yarn.

1 Circular loom control system

Circular loom central computer control system can be used

► Adjust the weft density

► Set the length of the Fabric

► Order order

► Manually operate the lifting system without turning it on and provide the following device parameter indications:

4 file automatic meter

Run time calculation

Change roll / cloth roll indication

► Equipment Evaluation System

The module determines the following additional parameters for each class and evaluates:

Running time of the device

The number of warp yarn breaks

Number of weft yarn breaks

Frequency of weft yarn use up

The weft yarn can be precisely adjusted in the open/stop state to optimize the fabric surface effect.

The above instructions are available in two languages (English/Chinese), with metric or imperial (inch) systems

2 Creel

2 creels total 1056 stations

The creel is designed according to the warp yarn spindle and can be loaded with a spindle with a diameter of 160mm.

Note: Not include Bobbin

1 Electrical configuration

► Lighting device

Equipment is equipped with 2 sets of 18W LED lighting tubes

► Heat sink

Not Equipped cooling fan in Tension frame.

But the fan interface and switch are reserved in the control cabinet.

► Let-off system

A total of 2 feed rollers, ensure that the warp yarns are smoothly fed into the main machine and maintain the real-time tension average.

Each let-off motor is controlled by load cell + Inverter control let-off motor. Motor power 0.2KW.

► Take-up system

Weft density is set by the circular loom main control system.

Take-up motor 0.55 KW power driven by a frequency converter.

► Central drive system

The inverter controls the three-phase motor and drives the CAM through the v-belt(two-stage of drive) to turn the CAM and drive the shuttle.

Main motor power is 4 KW

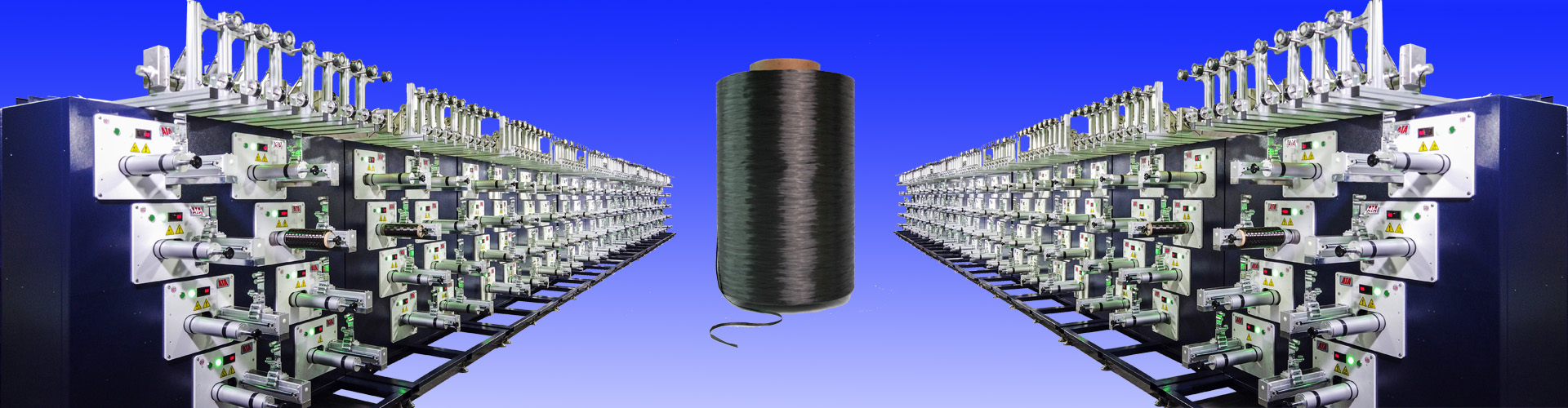

► Weft yarn detection

It is equipped with a photoelectric sensor and a proximity switch to control the weft yarn together and stop automatically when the weft yarn used up.

It is recommended to use black bobbin for best effect.

Remarks: Please use light colored tube for black yarn!

► Warp yarn break detection system

Each warp yarn is length compensated by tension adjuster and automatically stops the machine when yarn breaks.

The warp yarn breakage has an indicator light, and the 3 groups of indicator lights are distributed around the equipment.

► Weft yarn break detection system

1 sets of magnetic sensors monitor the weft yarn. In case of broken weft yarn, it will stop the machine automatically.

► Button boxes

There are 4 sets of button boxes around the main machine for easy operation. Each control box have inching button, stop buttons and start buttons; all are Schneider brand.

1 Fabric winding device

A friction type winding device is equipped with a load cell, and the winding motor is a 1.8NM torque motor.

We offer a 3″ roll core (standard size).

Remarks: 4".6" roll core can be selected - need to be customize

1 Bobbin saving

l There is a platform on each side of the circular loom for placing the bobbin.

* according to equipment requirements

We reserve the right to modify the technical parameters due to the continuous improvement of equipment technology.

| Working width | 800-1200mm |

| No. of Warp yarns* | 1008 pcs |

| No. of shuttles | 6pcs |

| Weft insertion* | 840ppm |

| Weft density | 20-55 /10 cm |

| Bobbin internal diameter ** | 35mm |

| Bobbin length ** | 220mm |

| Warp bobbin diameter(max.) | 160mm |

| Weft bobbin diameter(max.) | 110mm |

| Winding roll diameter(max.) | 1200mm |

| size | 13000X2800X3500mm |

| weight | 2500kg |

** Please specify if any special requirements

HOME

HOME