Max Diameter of Fabric φ1200mm

Max Cutting Speed 60pcs/min

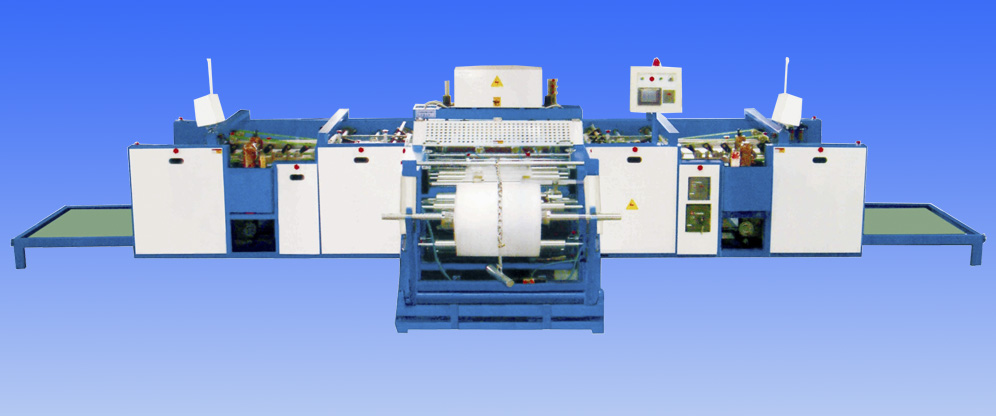

This unit is specially suitable for the bag making process of PP woven bags, and is widely used in the production of chemical, cement, grain, salt, feed and other packaging woven bag factories.

|

S/N |

Description |

Main Part |

Model |

Quantity |

Manufacturer |

Remarks |

|

1 |

Unwinder |

Unwinding Unit |

800 |

1set |

China |

The Unwinder is equipped with Auto Elevator to load fabric automatically, easy operation. EPC equipped, dancing Roller control Tension, Inverter control unwinding speed. |

|

Elevator |

|

1set |

China |

|||

|

EPC |

|

1set |

Taiwan |

|||

|

Dancing Roller |

|

1set |

China |

|||

|

Unwinding Motor |

1HP |

1set |

Taiwan |

|||

|

Inverter |

1HP |

1set |

ABB |

|||

|

2 |

Cutting Unit |

Vertical & Heat Cutter |

820 |

1set |

China |

Servo Motor controls feeding, Double Cam design for stable running Cutting. Mark Sensor to detect printed fabric, Servo control feeding length for non-printing fabric, achieves accurate cutting. Vertical & Heat Cutter with bag mouth open system. PLC & Inverter control cutting speed, sync control.

|

|

Mark Sensor |

|

1set |

Germany |

|||

|

Servo Motor |

2HP |

1set |

Yaskawa |

|||

|

Servo Controller |

2HP |

1set |

Yaskawa |

|||

|

Cutting Servo Motor |

1HP |

1set |

Yaskawa |

|||

|

Servo Controller |

1HP |

1set |

Yaskawa |

|||

|

Mouth Open System |

|

1set |

China |

|||

|

3 |

Transferring Unit

|

Servo Manipulator |

|

1 |

China |

Servo Manipulator transfers woven bag after cutting, Servo motor control the Manipulator, achieves precision transferring, and makes sewing quality. |

|

Servo Motor |

2HP |

1 |

Yaskawa |

|||

|

Servo Controller |

2HP |

1 |

Yaskawa |

|||

|

4 |

Folding & Sewing Unit (2 units) |

Sewing Head |

DN-2HS DN-2LHS |

Each 1 set |

Newlong |

Adopts Japanese Newlong Sewing Head, achieves high-speed & high-quality sewing. Equipped with single folding device, Inverter control sewing speed, PLC & Inverter for sync control

|

|

Sewing Motor |

1HP |

1set |

Taiwan |

|||

|

Sewing Inverter |

1HP |

1set |

ABB |

|||

|

Delivery Motor |

1HP |

1set |

Taiwan |

|||

|

Delivery Inverter |

1HP |

1set |

ABB |

|||

|

Single Folding Unit |

|

1set |

China |

|||

|

Thread Cutter |

|

1set |

Taiwan |

|||

|

5 |

Collector (2 units) |

Conveyor Belt |

|

1set |

Holland |

Sensor & PLC control, Auto Counting, Stacking & conveyor-belt advancing

|

|

Air Cylinder |

|

1set |

Taiwan |

|||

|

Sensor |

|

1set |

Taiwan |

|||

|

Collecting Motor |

0.5HP |

1set |

Taiwan |

| Item | Parameter | Remarks |

| Max Fabric Width | 800mm | |

| Max Diameter of Fabric | φ1200mm | |

| Max Cutting Speed | 60pcs/min | Bag within 1000mm |

| Cutting Length | 300-1300mm | |

| Cutting Accuracy | ±1.5mm | |

| Max Sewing Speed | 60-65pcs/min | Bag within 1000mm, width within 600mm |

| Stitch Range | 3.6-8mm | |

| Folding Width | 20-40mm | |

| Power connection | 11.5HP | |

| Machine weight | About 3.5T | |

| Dimension (lay-out) | 9200x3880x1360mm |

HOME

HOME