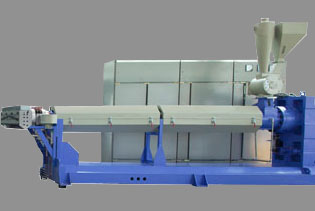

- Vacuum loading system brand: Shini TAIWAN

- Dia. of screw: Φ110mm; L/D of screw: 33:1

- Screw material: Nitride 38GrMoAl

- Max. rotation of screw: 115r/min

- Max. extrusion: 400kg/h

- Barrel heating use aluminum heater, solid relay control the heating

- Barrel heating total power and heating zones: 52.5kw 7zones

- Die-head using built-in stainless steel heating pipe and solid-state relay

- Length of die-head:1000MM

- Effective length:850mm

- Exceed film thickness: 0.07-0.35mm

- Die-head total heating power and heating zones: 18kw 6zones

- Main motor: Siemens AC motor

- Motor power:132kw

Tape stretching line AEG1000

Model AEG1000

Extrusion capacity Max.400kg/h

Die lip width 1000mm

Max. linear speed 450m/min

Extrusion capacity Max.400kg/h

Die lip width 1000mm

Max. linear speed 450m/min

Application

The machine is designed on the basis of PP material, if produce both PP & PE, the buyer should inform the seller in advance.

Each line consists of

Extruder

Haul-off unit/Slitting system

- 1.Haul-off unit

- Water remove plate 2 sets

- Water snap system 1 set motor power 3kw

- Film lifting system 1 set motor power 4kw

- Water absorb system 2 sets

- Water absorb motor power 3kw. 2.Slitting system

- Slitting shaft type: 6 side blade rotate

- Specification: non-stop changing blade, can be adjust up & down, and right & left.

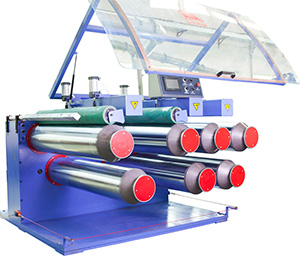

Drawing unit

- Roller size: Φ420mm (Bearing SKF)

- Roller surface deal: Plate Cr, mirror deal (Equip safety cover)

- Stretching 4 roller power: 18.5kw

- Max. Line speed: 450m/min

- Water chiller two roller motor power: 5.5kw

- Heating power of mold temperature controller: 24kw

- Oil heating two roller motor power: 5.5kw

Hot air oven

- Oven Size:6000X1400mm

- Effective using width: 1150mm

- Heating power: 70kw

- Fan power: 5.5kw×2sets

- Fan rotation speed: 1440r/min

- Up oven pneumatic open

- Heating using built-in heating pipe and power regulator

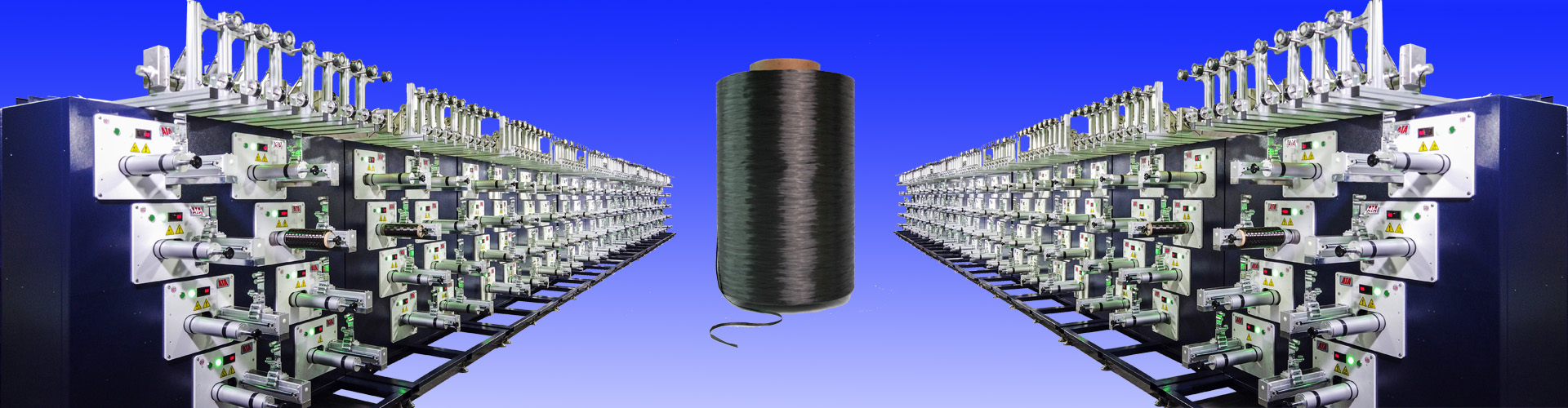

ATA600DH Winder

- According to different yarns, choose different winding parameters by setting of user independently, perfect spindles, wide usage;

- Adopting continuous winding technique, make sure the constant tension of the whole spindle, reduce yarn breakage rate in circular loom, reduce deviation of fabric width;

- Max. Winding Diameter up to 180 mm, reduce times to change spindles strongly, save labors, increasing usage time of warp yarn;

- Simple structure, little amounts of fast moving spare parts, high intellectualization.

Technical Parameter

| Working width | 850mm |

| Die lip width | 1000mm |

| Die material | Mold steel 4Cr13, surface by hard chrome treatment |

| Net film width | Approx.130mm |

| Extruder power | 132Kw AC motor |

| Extrusion capacity | Max.400kg/h |

| Screw speed | 20-115r/min |

| Screw | Screw dia. 110mm and L/D 33:1 |

| Screw and barrel material | 38 CrMoAlA Nitrogen treatment |

| Stretching ratio | 4-10 |

| Hot air oven length | 6000mm |

| Stretching roller size | Φ420×1350mm |

| Max. linear speed | 450m/min |

| Rated power | 350kw |

| Power consumption | 180kw |

| Winder number | 160spindles (This unit standard deploy) |

| Dimension | 42000x3300x3000mm |

| Weight | Around 30Tons |

HOME

HOME