-

1、 Use motor to unwind fiber actively, synchronous with the drive motor’s speed.2、 Each unwind position is individually tension controlled, and maintain the dynamic constant tension.3、 Special designed fiber threading system, ensure the best the impregnation effect.4、 Mechanic tensioning shaft, adaptable to various sizes of spindle, fast loading and unloading5、Powerful HMI real time monitoring the working status of each working unit, ensure a stable running.

Thermoplastic prepreg line

Model APC300

Melting temperature <350℃

Line speed 4-20m/min

Applicable resin materials PP/PPS/PA6

Melting temperature <350℃

Line speed 4-20m/min

Applicable resin materials PP/PPS/PA6

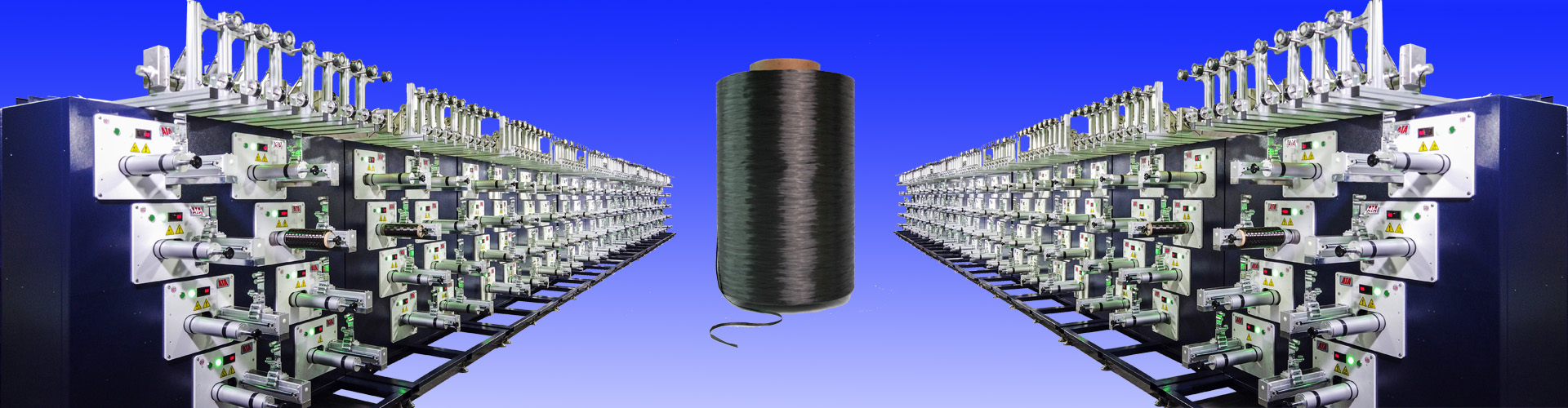

Application

Specific application fields: For producing carbon fiber, glass fiber and aramid fiber prepreg with thermoplastic resin. Products can be applied in aerospace and airplane, commercial prepreg, sports, wind blades, automobile , marine etc.

Pull the continuous fiber from unwinding creel, through the tension adjustment devices , and through the pre-heating equipment and fiber spreading device and got the pre-heated continuous fiber tows, screw extruder will melt the resin onto the glass fiber and enter into the impregnation mould, and through the fixing station by calender rollers, through the air cooling framework , edge trimming and finally rewound by the winders.

Production process:

Pull the continuous fiber from unwinding creel, through the tension adjustment devices , and through the pre-heating equipment and fiber spreading device and got the pre-heated continuous fiber tows, screw extruder will melt the resin onto the glass fiber and enter into the impregnation mould, and through the fixing station by calender rollers, through the air cooling framework , edge trimming and finally rewound by the winders.

Components features descriptions:

Driven control unwinding creel

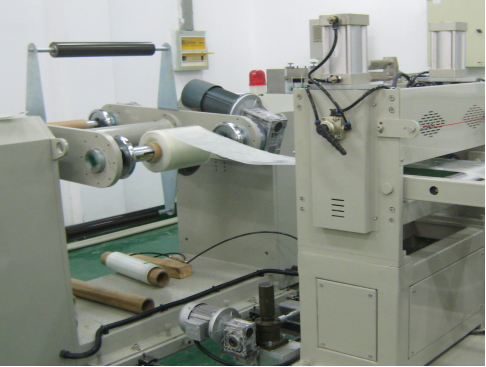

Fiber spreading heating Device

-

1、 Spreading width adjustable2、 Use infrared heating , fast heating , temperature adjustable and real time monitoring.

Double screw extruder

-

1、 Extrusion volume can be adjustable at any time.2、 Extrusion temperature adjustable and real time monitoring.3、 Extrusion die real time monitored, safety guaranteed.

Impregnation sheet mould

-

1、 Use high quality heat resistant alloy steel with long service life.2、 Heated integrated, temperature adjustable and real time monitoring.3、 The internal mould is wave channel, gap height adjustable to ensure the fine impregnation.

Vertical Three rollers calender machine

-

1、 Roller temperature adjustable , heating media is water.2、Hydraulic pressure to clamp, open and close, roller gap adjustable.

Air cooling edge trimming device

-

1、 Use air cooling , simple structure.2、 Prepreg sheet width adjustable.3、 Trimmed edge recyclable.

Puling rewinder

-

1、 Equip with encoder and length counter.2、 Roller material is wear resistant rubber, no damage to the product.3、 Double winding positions, with length counting and alarm function.4、 With torque control and automatic speed adjustment.

Final product features

-

1、 Fiber spread evenly.2、 Fully impregnated3、 Low void content.4、 High performance and low cost

Technical Parameters

| Items | APG300 | APC300 |

| Fiber types | GF | CF |

| Applicable resin systems | PP/PPS/PA6 prepreg production. | |

| Melting temperature | <350℃ | |

| Fiber volume | Volume fraction 20%-50% (mass fraction 30-60%) | |

| Prepreg thickness | 0.15-0.40mm | |

| Prepreg width | 300mm(effective width after edge trimmed) | |

| Stable impregnation speed | 4-20m/min | |

| Surface quality | Shinny, roughness<0.1 | |

| Impregnation method | Resin filming impregnation or Die impregnation | |

| Input power | ≤150kw | |

| Power supply | 380v,50hz | |

HOME

HOME